ZM Cutting

Dedicated to CNC machining centres for stone cutting

Overview

Software specialised in the operation and management of every aspect of CNC machining centres for cutting stone materials such as marble, granite, ceramics and the like. Its numerous functionalities allow an overall efficiency improvement of the stone working process. The ZM CUTTING software has all the functionalities to perform a large number of machining operations.

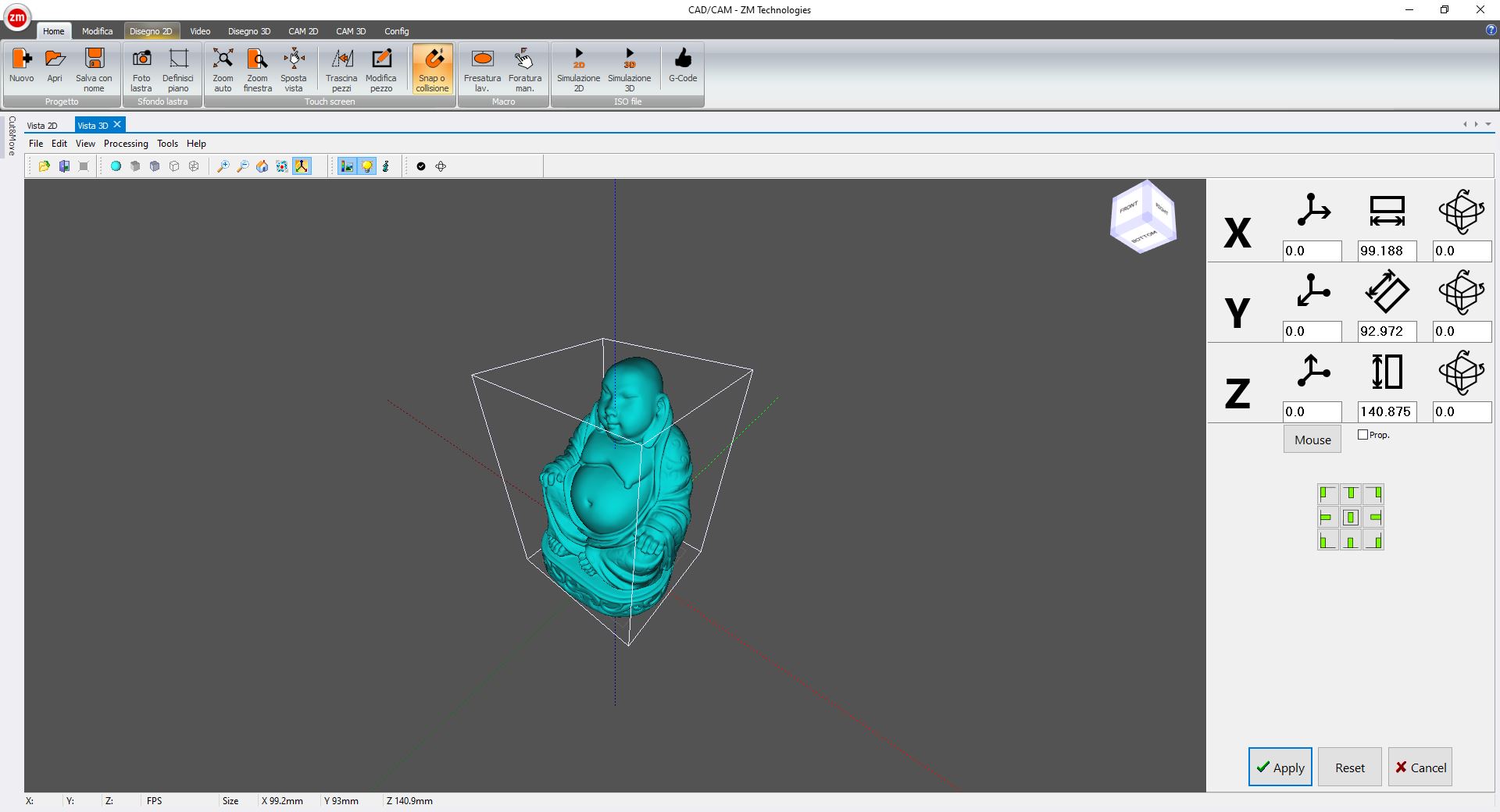

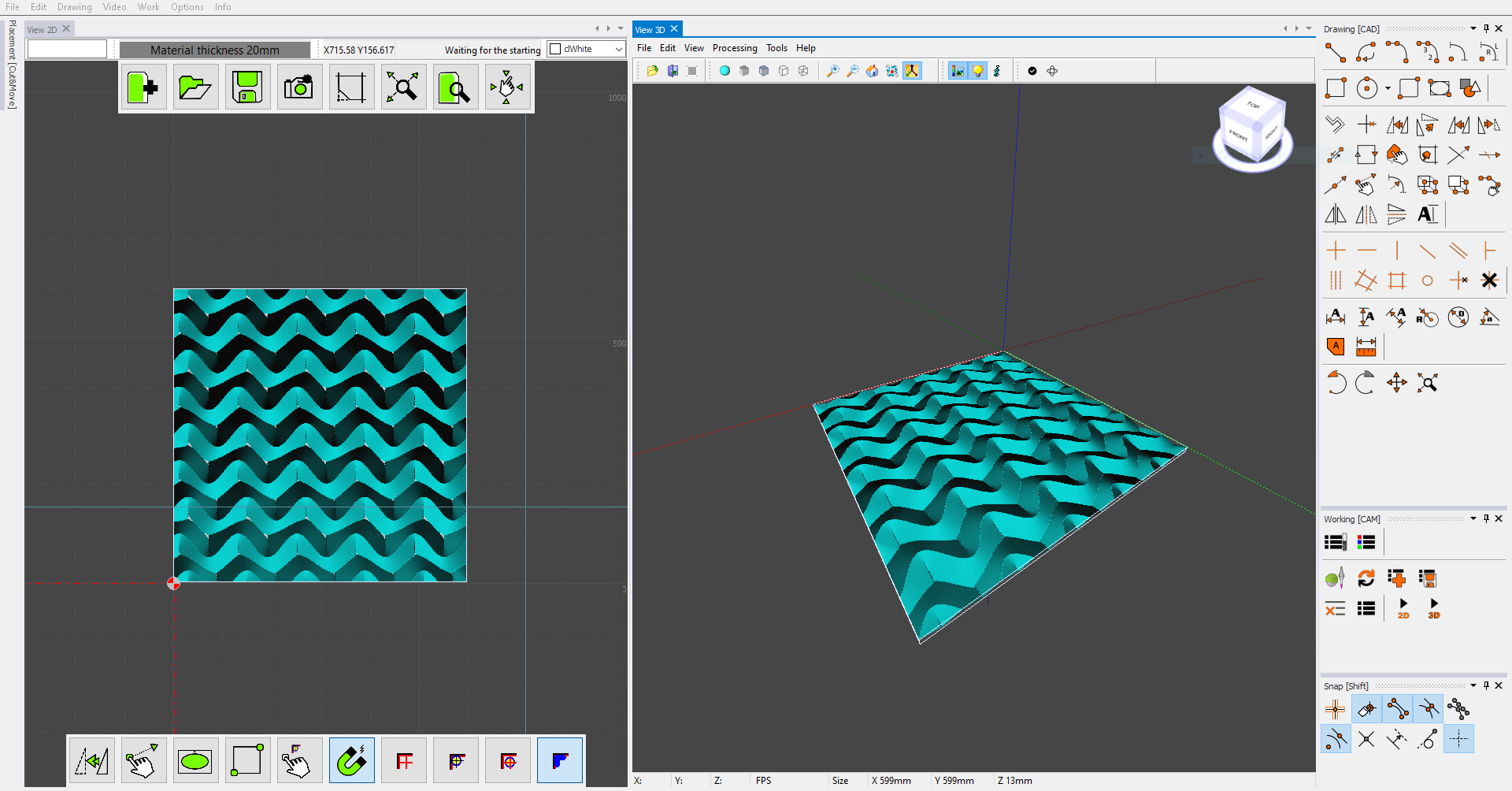

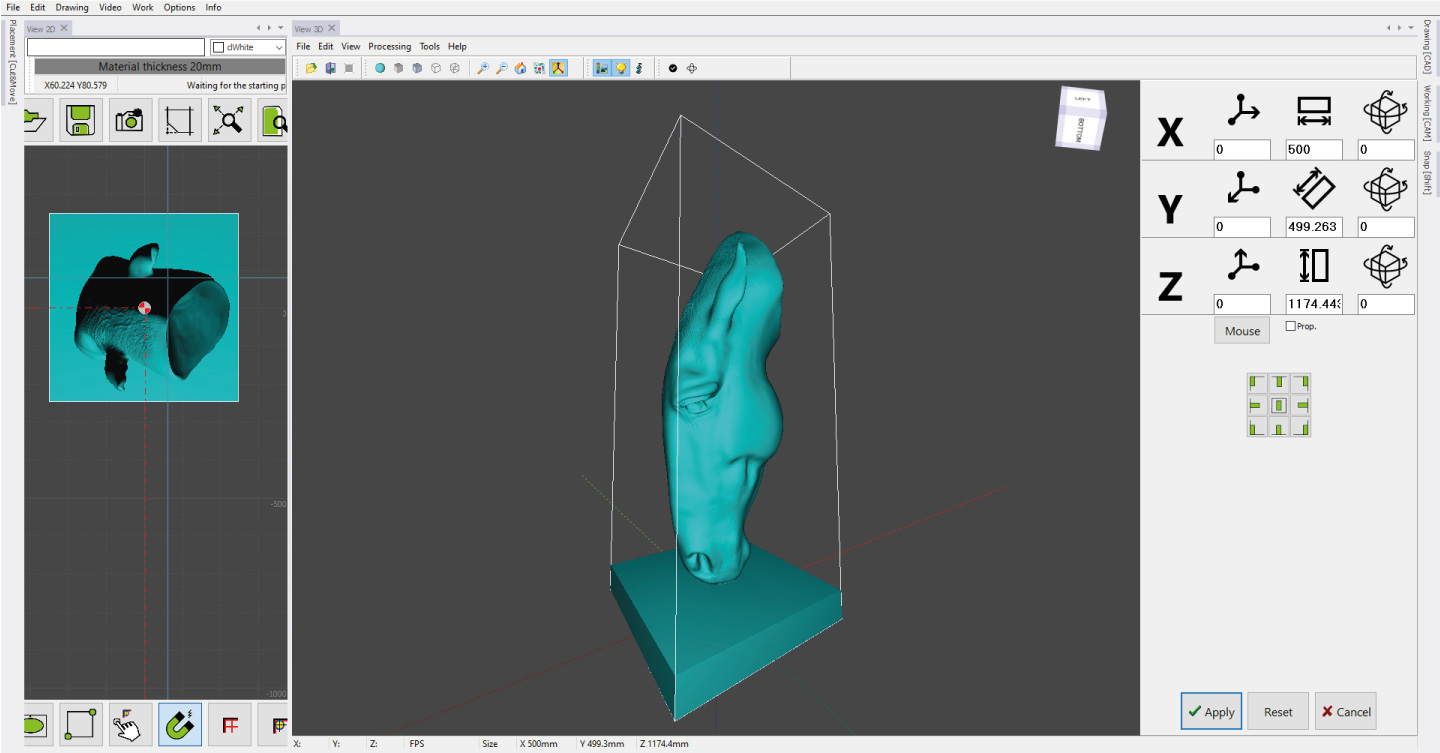

CAD machining

CAM machining

Zm cutting

Manual or automatic nesting

ZM CUTTING also has an integrated nesting system that allows the arrangement of shapes (pieces and sub-pieces) on the material sheet in automatic or manual mode. A useful solution for optimising cutting and avoiding waste of raw material.

Integrated camera

The software includes the ZM FOTO programme, which uses digital cameras integrated in the machine to capture real images of the slabs being processed. The integrated camera also allows filming for the completion of cuts with waterjet or drill/socket.

Drawing

ZM CUTTING has a 2D CAD drawing function.

Intelligent system

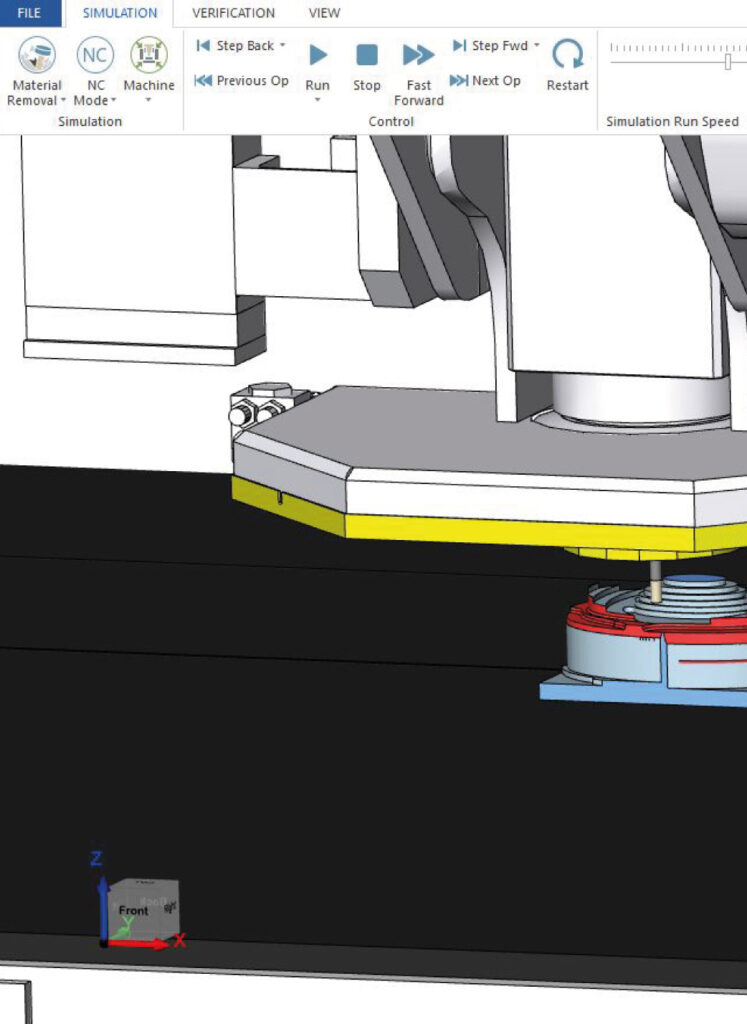

An intelligent system enables the management of slab cutting, solid simulation with material removal and handling of workpieces by means of suction cups.

Collision control

The collision detection function precisely calculates the path of each tool used in the CNC machining centre in order to prevent any impact.

Tool path optimisation

ZM CUTTING is designed to calculate the tool path and optimise disc cutting trajectories.