ZM Waterjet

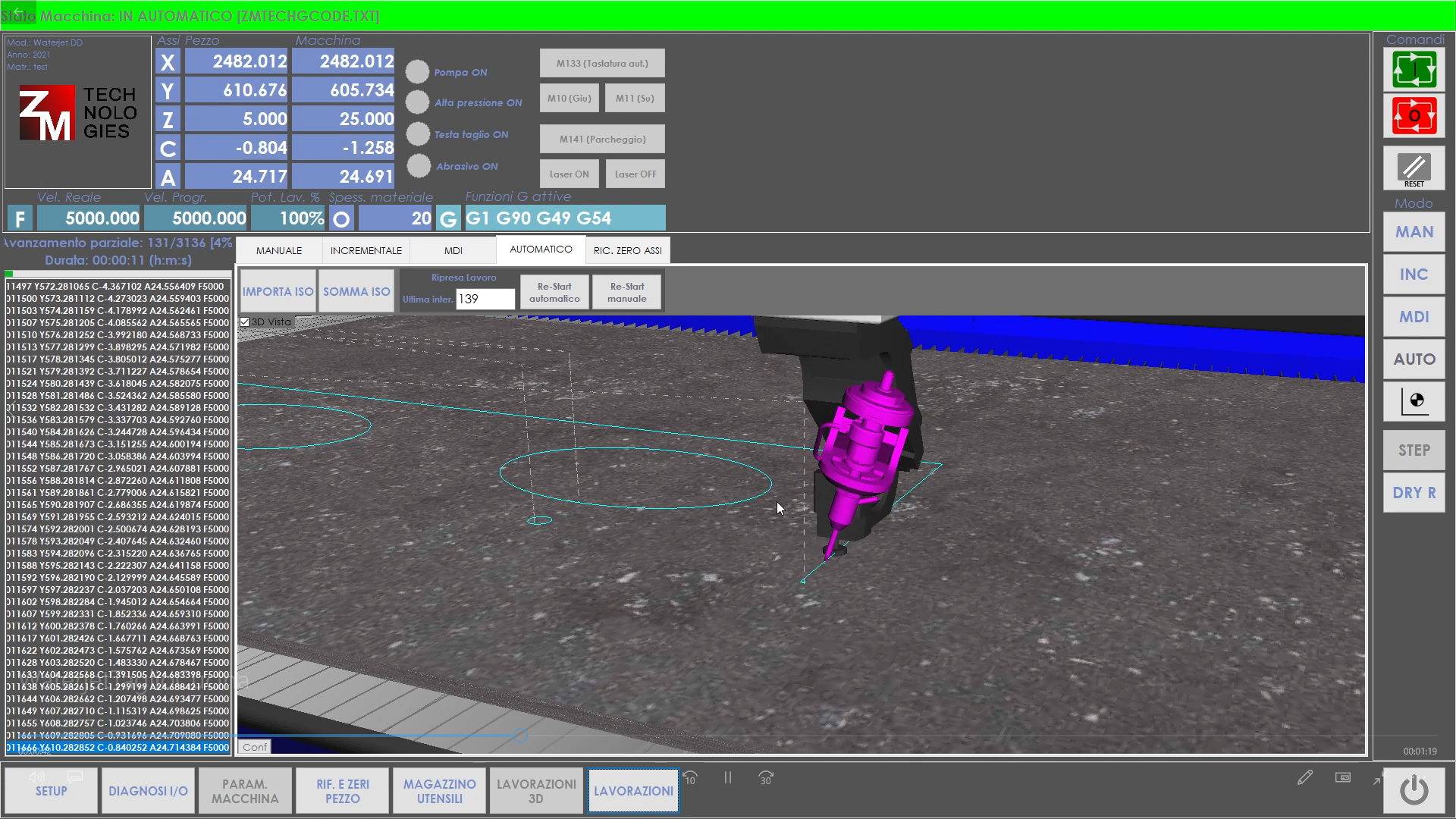

Software with 3- and 5-axis waterjet technology for high-pressure waterjet cutting

Software for operating CNC machining centres with 3- and 5-axis waterjet technology, intended for cutting stone materials by high-pressure waterjet.

Machining

ZM Waterjet enables the machining of profiles of marble slabs or other stone materials, mainly for the creation of window sills, kitchen tops, sinks and thresholds.

The software has three types of machining: vertical ribs, ribs with constant inclination and ribs with variable inclination angle on 5 axes.

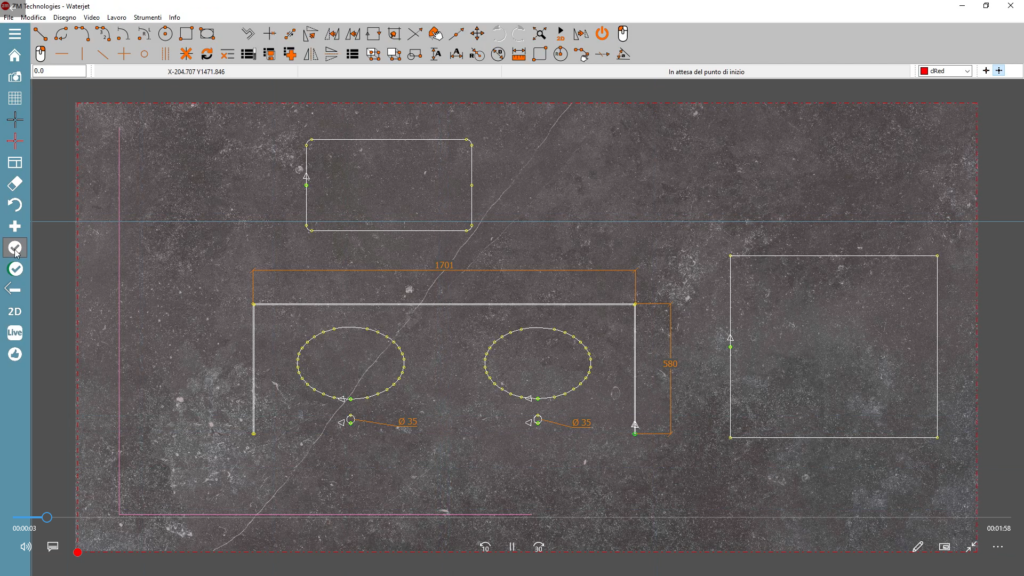

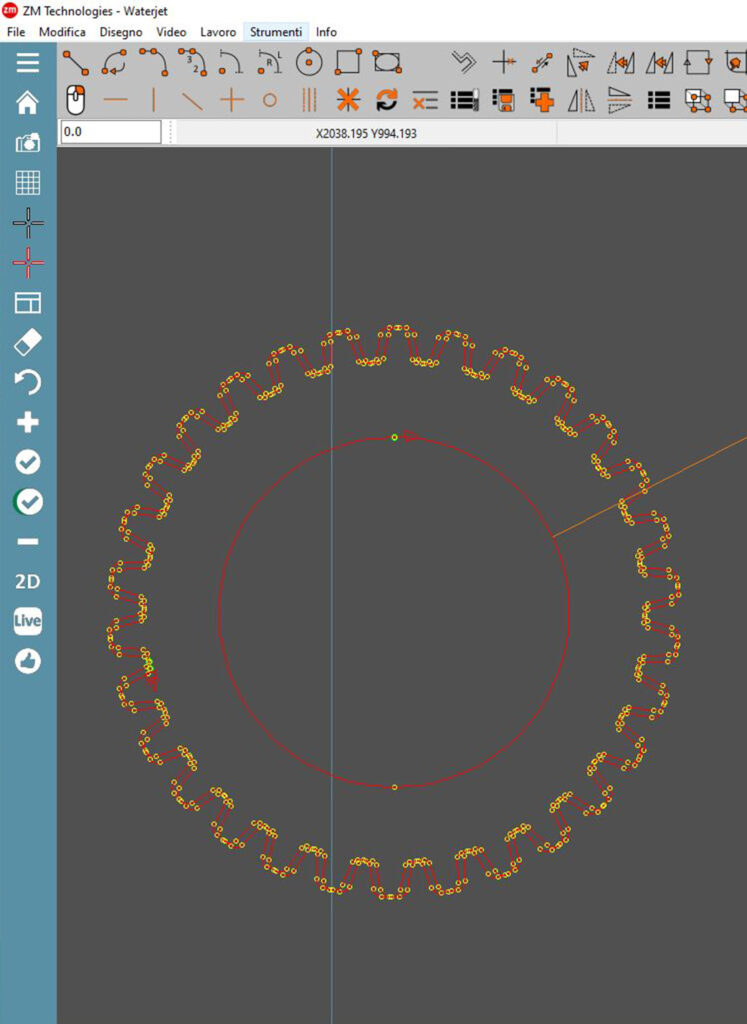

Drawing and design

Definition of templates using 2D CAD tools, import of DXF/DWG files, acquisition of templates with a photo-digitizer and lists in proprietary formats such as Excel and CSV.

Manual or automatic nesting

The integrated nesting system allows the arrangement of the templates (previously grouped in cutting sequences) on the material sheet in automatic or manual mode. A useful solution for optimising cutting and avoiding waste of raw material.

Complex drawings

Simple and intuitive management for the creation of complex designs for inlays and flooring.

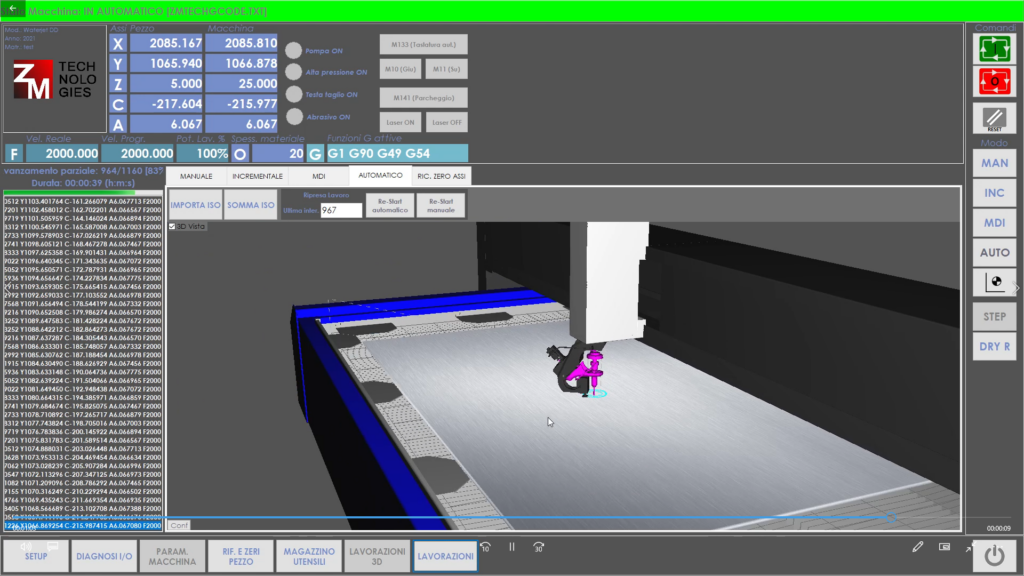

Integrated graphic simulation

An integrated graphic simulation environment allows the result of machining operations to be verified in real time, for an overall efficiency improvement of the machining centre's production process.

Collision control

The collision detection function precisely calculates the path of each tool used in the CNC machining centre in order to prevent any impact.

Nesting

Automatic management of material probing to achieve the highest precision in stone machining and the most efficient production process.