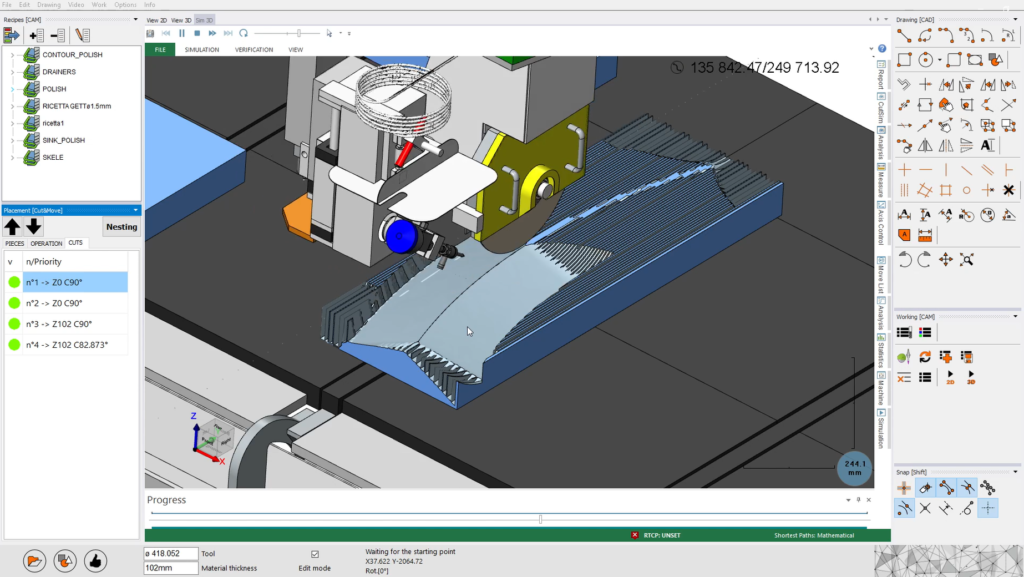

ZM Contour

Software for machining flat surfaces such as kitchen and bathroom worktops.

Specific software for the design, modelling and machining of flat surfaces such as kitchen and bathroom tops.

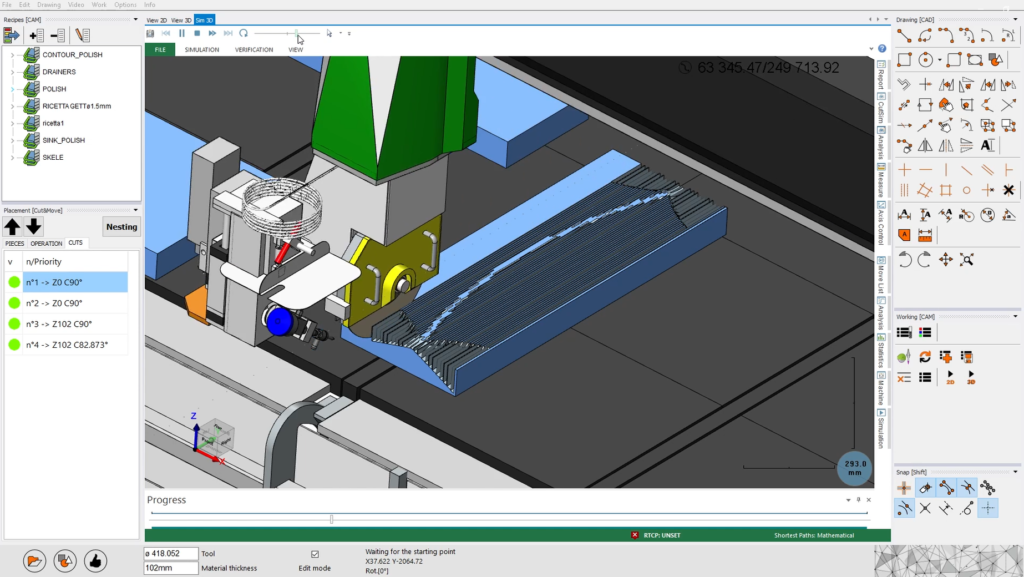

Rough-cutting

The first stone processing phase, the phase in which excess material is removed, includes the following operations:

- Straight cutting

- Curved cut

- Inclined cut

- Grooving

- Disk engraving

- V-Groove

Finishing

The ZM CONTOUR software allows a wide range of finishes:

- Deburring

- Polishing

- Cutting/finishing holes

- Sink and hobs

- Routing with milling cutter

- Profiling

- Tap holes

Drawing and design

Drawing can be realised through lists in proprietary formats (Excel, CSV) or by acquisition of templates with a photo-digitizer.

Import from external CAD

In addition to being equipped with 2D CAD tools, ZM CONTOUR allows the import of files in DXF/DWG formats to create a complete design layout.

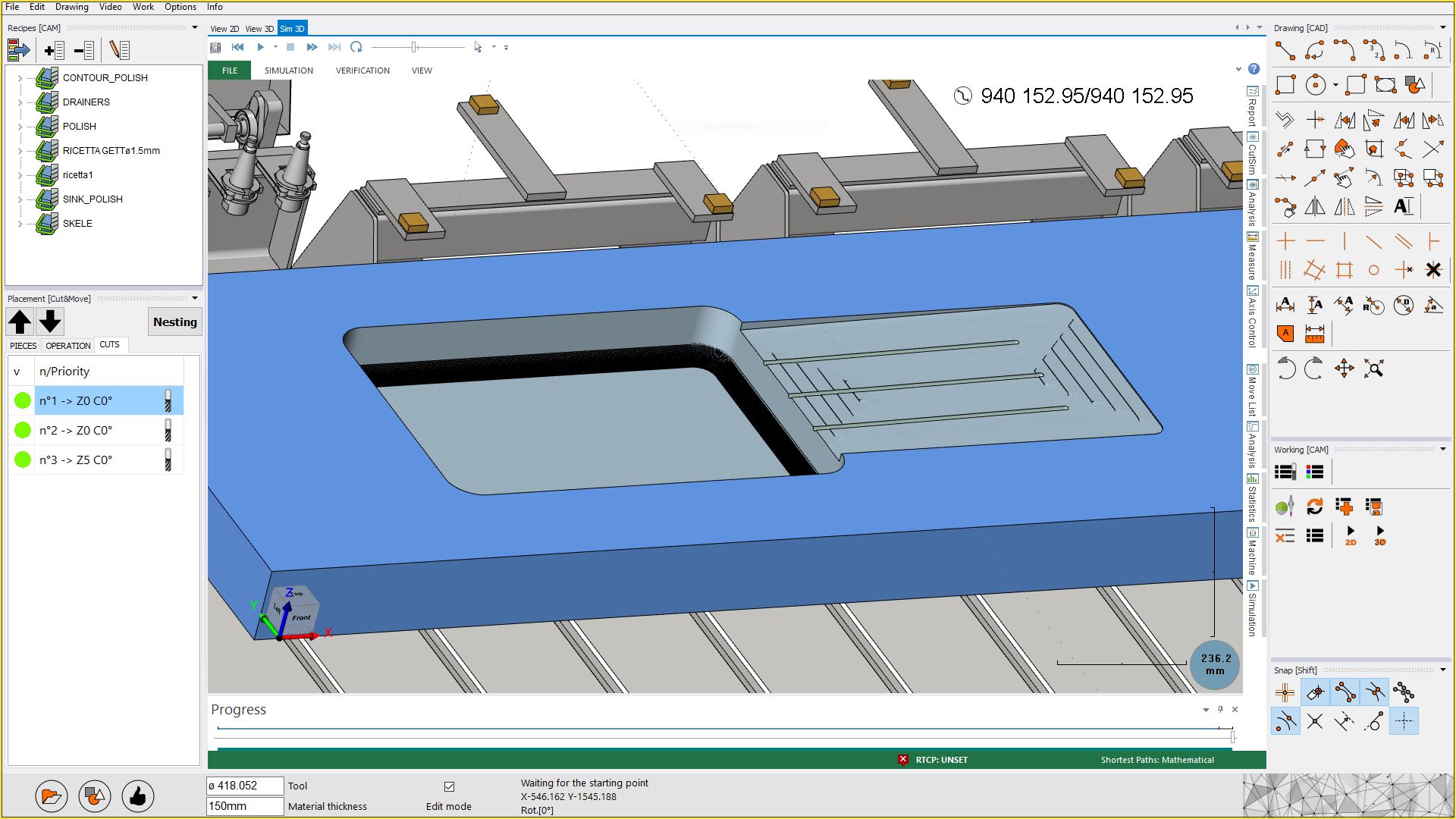

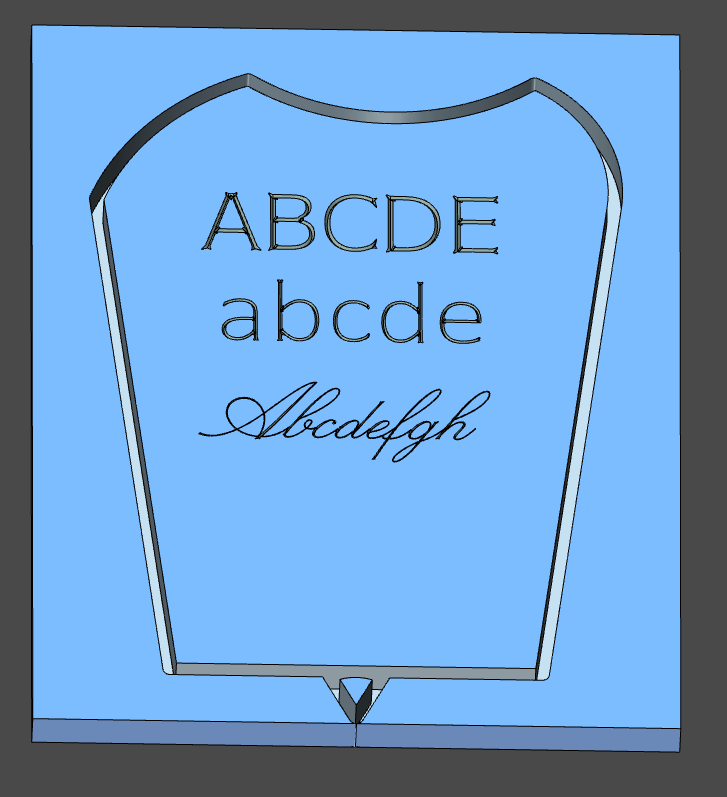

Rendering

A 3D rendering window allows a preview of the finished work to be displayed, with the aim of resolving any errors or problems before the machine or CNC machining process begins

2.5D machining

The software is built to allow the technician to create free 2.5D machining.

Manual or automatic nesting

The integrated nesting system allows the layout of the shapes (previously grouped in cutting sequences) on the sheet of material either automatically or manually. A useful solution to optimise cutting and avoid wasting raw material.

Autocorrection by probing

A self-correction function by probing the sheet is available for each type of machining, with the aim of compensating for variations in material thickness.

Cutting technologies

Software-supported cutting technologies are by disc, cutter, hole and pressurised water (waterjet).