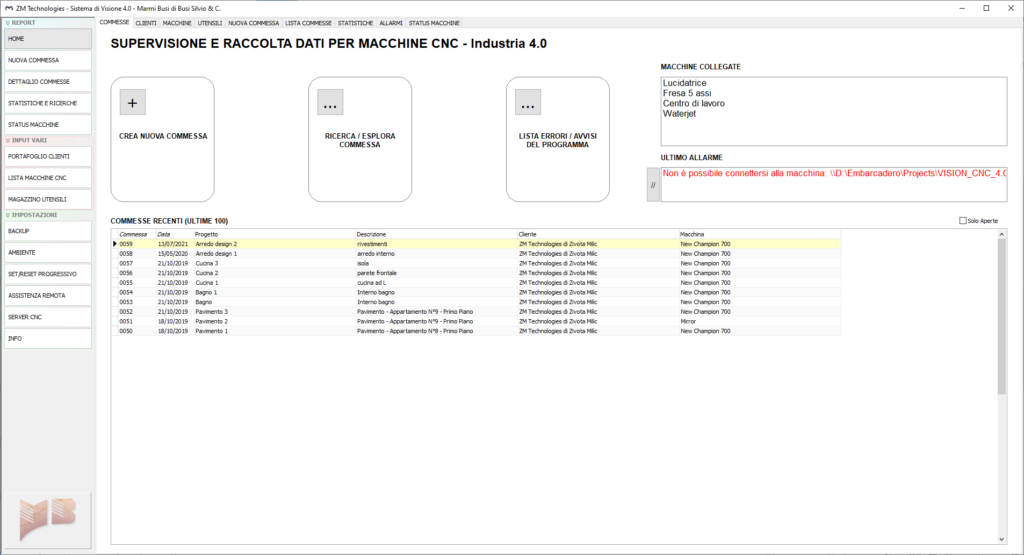

ZM Smart Factory

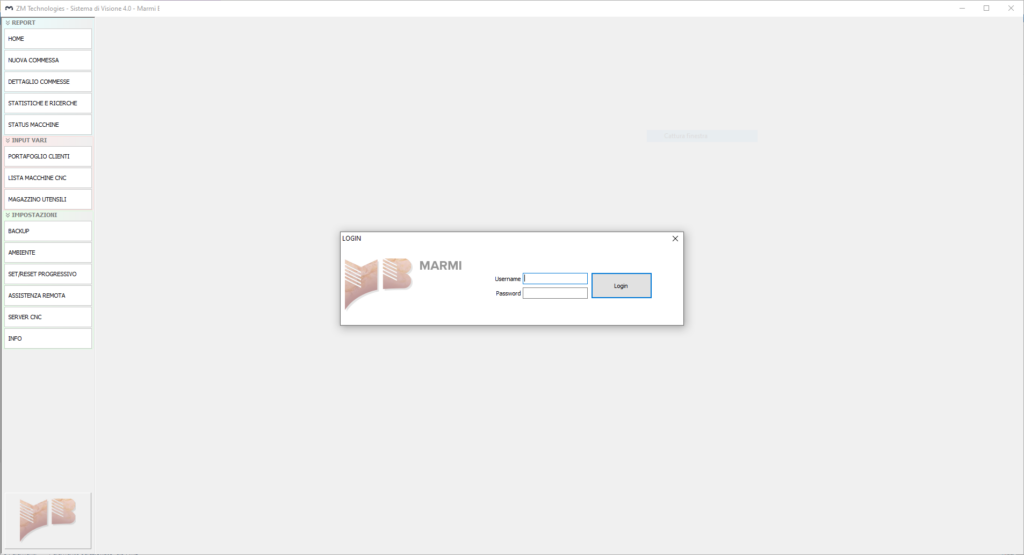

Software with intelligent production systems, which collects and supervises machine data. Protocol for data exchange with the machine via Ethernet port or Wi-Fi network. Compatible with Windows 10 and 11 systems.

Design

Features wizards to guide the user through the process of creating codes and compiling profiles to prepare inputs for machine operation.

Once created, inputs are transmitted via Ethernet port or WiFi network.

In addition to taking care of machine operation, the software allows the management of numerous types of data such as customer master data, machine master data and all information on their components and tools.

Production

Inputs are sent to the connected machines to start the operation and production process.

The software allows the work to be programmed, with the possibility of repeating profiles already acquired by the machine several times, managing the stock and consumption of the equipment.

On the basis of the data collected, it performs a predictive action, alerting operators in case of the need for maintenance, replacement of components or when the preset operating hours have been reached.

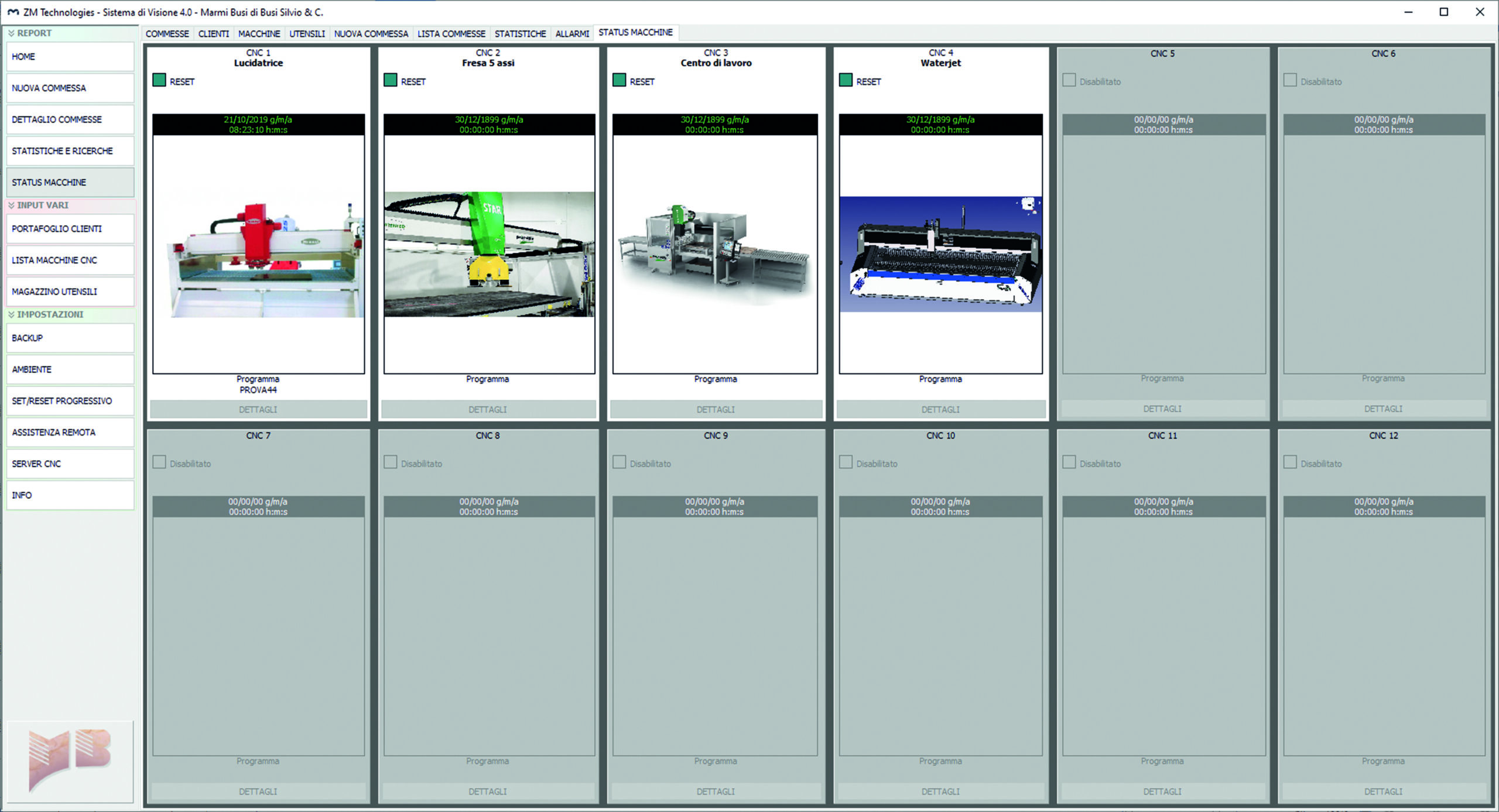

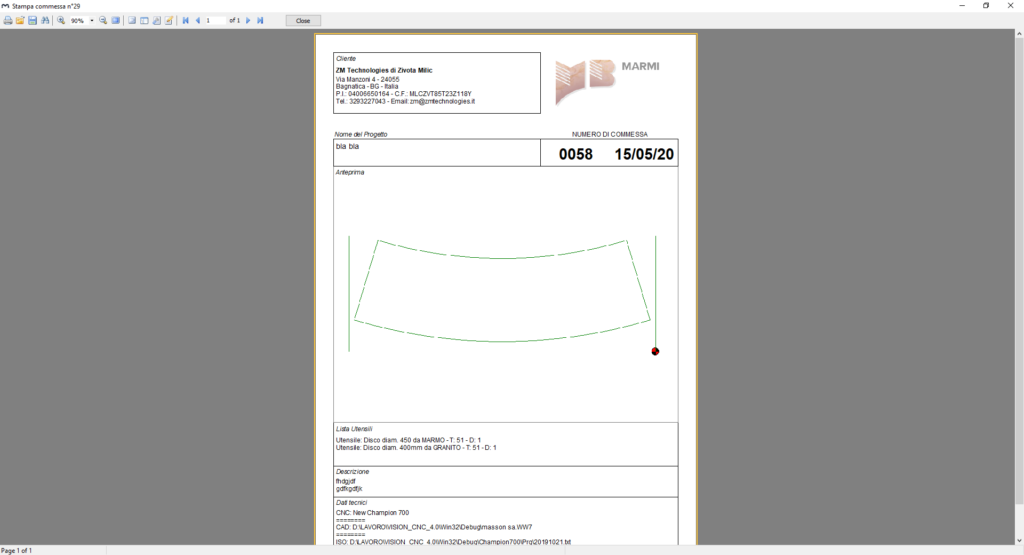

Monitoring

It is designed to ensure detailed and continuous monitoring of work progress, the wear status of the components of the various machines, alerts and alarms.

The system is integrated with remote diagnostics and remote assistance software via Teamviewer or Anydesk and allows work reports to be printed in PDF format, according to the layout defined on the machine.